Add to Cart

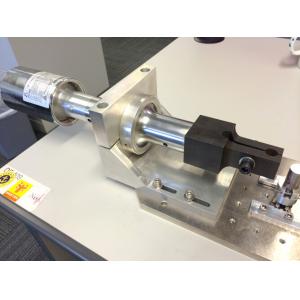

High Power Ultrasonic Assisted Machining High Precision For Tapping Titanium Rod

The ultrasonic vibration consists of

an ultrasonic spindle kit, a constant pressure feed system and a coolant system.

| Frequency | 20 Khz |

| Output Power | 1000 W |

| Voltage | 220 V |

| Switch | Handle or foot switch |

| Power Adjusting | Step or continuous |

| Working Time Control | 24 Hours |

| Weignt | 30 KG ( Determined by the size of the horn ) |

| Generator | Digital Generator |

Principle:

ultrasonic machining process uses a power supply that converts conventional line voltage to 20KHz

electrical energy.

This high-frequency electrical energy is provided to a piezoelectric converter that changes high frequency electrical energy into mechanical motion.

The ultrasonic motion from the converter is amplified and transmitted to the horn and cutting tool.

This causes the horn and attached cutting tool to vibrate perpendicularly to the tool face thousands

of times per second with no side to side motion.

Functions:

Ultrasonic vibration during the machining cycle to accomplish rapid material removal, improved surface

quality, and maximized tool life.

Ultrasonic machining provides a number of advantages compared to conventional machining techniques.

1. Both conductive and nonconductive materials can be machined.

2. Complex three-dimensional contours can be machined as quickly as simple shapes.

3. The process does not produce a heat-affected zone or cause any chemical/electrical alterations

on the workpiece surface.

4. A compressive residual stress generated on the workpiece surface can increase the high- cycle fatigue

strength of the machined part.

Applications:

Improvements led to the development of a machine comprising a rotating ultrasonic transducer. The rotating transducer head made it possible to precisely machine stationary workpieces to close tolerances. With different shaped tools, the range of operations could be extended to end milling, tee slotting, dovetail cutting, screw threading, and internal and external grinding.

high power ultrasonic assisted machining for tapping titanium rod , high precision , ultrasonic vibration